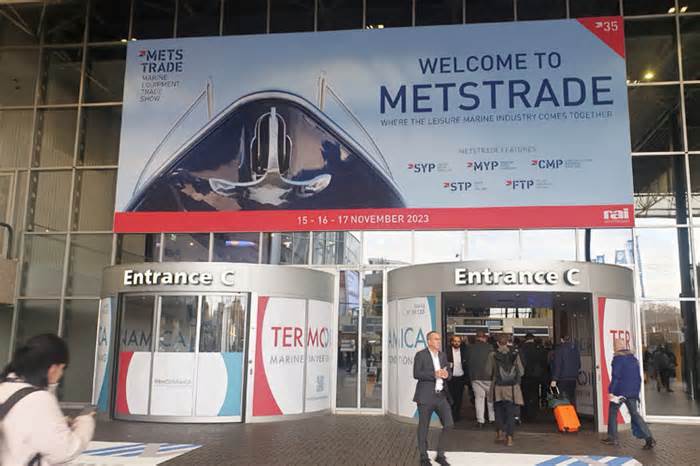

The 35th edition of Metstrade in Amsterdam ended in November 2023. Enthusiasm, participation and record attendance were present: 1,540 exhibitors from 53 countries in 11 halls, crowded halls welcomed 28,900 visitors from 18,630 visitors from 130 nationalities. The number of industry pavilions has also increased this year, with the opening of the Foil Technologies pavilion and the Startup pavilion, along with the Superyacht pavilion, the Construction Materials (CMP) pavilion and the Marina pavilion

5 minutes, 20 seconds

ICOMIA has presented its report “Pathways to decarbonised propulsion for the recreational boating sector”. “When you’re working day-to-day, you may not be aware of the scale, variety, speed of innovation and new advancements that are taking place in the boating industry. There are so many hobbies and enthusiasm in our industry and to see them condensed into one position is exciting,” said Joe Lynch, Executive Director of ICOMIA.

“The maritime industry is evolving at an appropriate speed to meet the many opportunities and demanding situations it faces. We are pleased to contribute to this 35th anniversary edition with several new and welcome features aimed at sustainability, people, skills, inclusion and innovation,” said Niels Klarenbeek, Director of Metstrade.

The Building Materials Pavilion, which showcased raw fabrics and sustainability in yacht building, welcomed many exhibitors and a large turnout this year. The underlying theme is environmental coverage and sustainability. Increasing sensitivity to nature and the environment has increased science and technology efforts to identify strategies and technologies focused on renewable resources, renewable energy, and eco-sustainable fabrics.

Flax fibers or volcanic rock (basalt), resins of vegetable origin. Nature can provide the foundational fabrics for shipbuilding composites to update fabrics that have been widely used for 70 years. Developers of specialized vessels are already adopting new recyclable fabrics and proving their sustainability. Mass production shipyards are sticking to it step by step, streamlining new environmentally friendly parts so that they are market-ready and profitable.

At a time when the maritime industry is looking for answers capable of addressing environmental concerns, specifically with regard to their effects on the world’s ecosystems and resources, one example is above all that of Greenboats, a pioneer in the development of plant fibre composites (NFC) and represents a driving force for eco-sustainable curtain responses in the progression of composites (Figure 1). Recently, they announced the partnership with Fassmer that will enable the production of their eco-friendly composite fabrics at the Fassmer plant. This collaboration will create an exclusive production site in the world, highlighted for its scale of production and sustainability in the progress of NFC.

As a component of this partnership, a pioneering plant for the production of composite laminates reinforced with vegetable fibers is taking shape. Designed to produce laminates up to 6m x 2. 5m, the plant will use environmentally friendly flax fibres and bio-resins. High-performance materials, a sustainable commitment with products with significantly reduced CO2 emissions.

Friedrich J. Deimann, founder and CEO of Greenboats, highlights the importance of this collaboration, which represents a vital step towards the industrialization of new materials. Building the lightest boat imaginable is a number one goal, and not just for racing boats. At the CMP, Hypetex showcased a coloured carbon fibre, which was effectively used to visually create the logo that is part of the hull of an IMOCA 60 racing yacht. By leveraging sustainable flax fibers, Hypetex continues to overcome the barriers of the composites industry. The FlaxTex™ generation offers a unique process of coloring and coating flax fibers, allowing for the integration of aesthetics into products (Figures 2 and 3). This generation opens up a world of possibilities for designers and brands looking to combine durability with striking visual appeal.

Another plant fabric that is becoming increasingly attractive to the nautical industry is cork. Amorim, brought Navicork for the maritime bridge industry, created for other types of ships, using cork as a raw fabric. Cork is a one hundred percent plant-based, reusable and recyclable fabric. For curtains, lightweight, resistant, flexible and with just the right degrees of thermal and acoustic insulation, cork has unrivalled qualities. Navicork FD01, the evolved solution for decking, offers exquisite aesthetics and a soft, cool feel underfoot, offering ordinary comfort and grip (Figure 4).

3D printing was well represented at this year’s Metstrade, demonstrating the growing interest of the shipbuilding industry.

Caracol, a key player in large-format robotic 3D printing, with nearly 10 years of experience in 3D printing parts for complex sectors, and V2 Astilleros Y Barcos S. L. , Spain’s leading shipbuilder, have announced their collaboration Its aim is to explore and expand new responses for the shipbuilding sector and produce sustainable vessels and structural factors, recycled fabrics and large-format additive manufacturing. V2 Boats and Caracol will combine the know-how matured over years of painting in the sector.

V2 Boats will install a Heron AM platform in Spain to manufacture boats – adding complete hulls and parts such as superstructures, furniture, etc. – and corporations in the maritime sector, both in the Iberian Peninsula and in the LATAM region.

Through this partnership, the companies believe that it will be possible to further expand and advance the use of large format 3D printing, bringing it into production of finished boats and parts.

Massivit exhibited the Massivit 10000 and 10000-G, which enable the automated production of molds and tools for the manufacture of composites. Both aimed to produce large, complex custom-made molds, making it possible to print in a matter of days, rather than weeks. , a tool that would bring wonderful advantages to the yacht builder.

In the the FTP pavilion, Addyx introduced the WSM-170, a 3D printable polymer that creates a water-soluble expanding mandrel, revolutionising the design and production of hollow tubular components in composite material. It was created with the aim of strategically combining additive manufacturing with the advanced composite materials industry, facilitating the creation of hollow components in composite material with complex geometry.

The WSM-170 is unique. It works as a rigid rolling medium at room temperature, which also allows deflation directly into the chuck. During curing, it acts like a silicone rubber, eliminating the need for an internal bag, but with the use of an external mold. After curing, the mandrel is gently dissolved in solvent-free water, leaving the hollow composite component with no residue, resulting in a curtain with low environmental impact (Figure 6).

Within the Foiling Technology Pavilion, Marin, the largest institute of maritime studies in the Netherlands, presented The Foil Design JIP, a task that recently involved 8 participants but open to new participants who can contribute to this initiative. The task, now in its second year, is expected to be completed by January 2024.

What does the long term hold? From what we’ve seen, the main topics are films, electric motors, and environmentally friendly, recyclable, and low-emission fabrics. We’ll see a lot of studies faithful to tissues, generation, and structural issues in the coming years. Save the date for JEC World 2024 to learn about the newest fabrics and technologies.

Advertisement

Enterprise

Shipping & Shipbuilding

You can create a free technological watch and keep you updated about all these subjects.

Stay up-to-date with the latest compound news straight to your inbox. Subscribe to French and JEC Composites e-charts free of charge.