Making all-electric, cellular and off-road appliances viable is a complex engineering proposition. One of the pillars of this technique is to find a way to recharge the vehicle’s batteries. The use of a diesel generator makes no sense when one of the number one objectives of the all-electric concept is to propose a greener technique with a minimal carbon footprint.

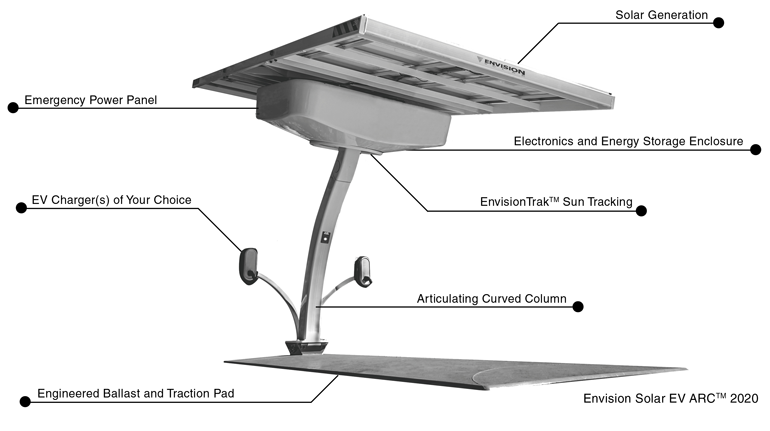

When our company Envision Solar accepted the challenge, through the construction of what we call the renewable charger for autonomous electric vehicles or EV ARC 2020, we learned two main problems. The first was to make sure he painted in all climates and conditions. The timing was to be certain that it would operate at maximum power while still being undeniable and reliable.

That’s how we solve those problems.

The design of a cell phone charger that works in all climates, from the bloodless winter in New York to the afternoon in the Nevada desert, is not insignificant. It deserves to work in excessive situations and when there is no sunlight to force the solar panels. This meant that force would also have to be stored for use at all times, which would lead to batteries and all complex appliances needed to administer them, as well as related electronics to store, oppose and supply usable electrical energy to autocellulars and machinery used. through our customers.

Batteries and related electronics paint to the maximum successfully and safely in an express temperature diversity that we call the Goldilocks area (neither too hot nor too incrusal, simply correct). Fortunately, this diversity is wide, starting at 32 degrees F (0 degrees Fahrenheit) and ending just under 104 degrees Fahrenheit (40 degrees Fahrenheit). As a general rule, the way to keep an object at a somewhat constant temperature is to heat it when it is too exangia and cool it when it is too hot. However, such energy-intensive processes would create unacceptable parasitic consumption from a limited source of electrical energy (solar energy). Using all the energy produced through the solar panel to keep the Goldilocks domain impassable. We had to design a product that could simply passively its own temperature.

THE EV ARC. Envision Solar

The law of the moment of thermodynamics and entropy at our disposal. Asking how to exploit them in our favor, when it’s an advantage, and mitigate their effects when they ran against us. The law of the moment of thermodynamics says that hot elements are constantly cooled (abandoning thermal energy and moving to a state of entropy). This law is the explanation for why ice cubes melt (when the ambient heat moves towards them) and the hot soup cools (giving heat to suit the conditions of the environment). Keeping soup warm in a blood-free environment is easy; isolation does the trick. Thermos are not smart, but they are smart to slow down the law of thermodynamics. Cooling a soup in a warm environment is a little more complicated, as any child who has impatiently blown the soup with their spoon on the table can be seen.

In the end, we combine 3 passive cooling strategies (convection, conduction and phase replacement) to handle heat conditions. For the cold, we reduced airflow, added insulation, and used the heat generated by the general operations of EV ARC. In general, these strategies allow the charger to work in the United States.

The next challenge we had to succeed on the most fundamental aspects and related to the basics of solar energy. That means maximizing efficiency. There are two tactics to do this: enlarge the panels or make them denser in terms of the number of cells that produce energy depending on the inches. Expanding solar panels was never an option because the ARC EV had to be cellular and have compatibility in a singles parking lot. This meant that we had to increase the power density, or at least the actual density of the solar panel, one way or another.

The time of day with the highest energy density is typically around noon (or thereabouts) when the sun is at its highest point in the sky. This lets photons hit the array as perpendicularly as possible, maximizing its production. To get more “noon,” we had to add solar tracking. It keeps the array properly aimed toward the sun during the as much of the day as possible. This, in effect, shifts noon and extends the window of maximum effectiveness.

There is already a wide variety of tracking technologies on the market ranging from the fundamentally excessive to the overly complex. However, the more complex the technology, the more complex it becomes. As in many engineering spaces, complexity increases the likelihood of failure and increases costs.

We also found that photovoltaic cells are insensitive to the accuracy of aiming. In fact, you get the maximum production profit by keeping the modules at less than 20 degrees. to aim directly at the sun. Any precise construction leads to a significant increase in complexity, hazards and costs, but only a marginal increase in electricity production.

The EV ARC is self-contained and fits a single parking space.

We temporarily opted for an undeniable and very physically powerful tracking solution that would provide the maximum of all gains with a much lower probability of failure. Our engineers have designed undeniable but sufficient tracking algorithms for the highest-reliable hardware in an EnvisionTrak patented solar tracker.

EnvisionTrak tilts the matrix to keep it directed towards the sun. But that rotate or roll the table, as is not uncommon with maximum tracking devices, we fold the column to the maximum sensitivity to the one that the table is located. This is important for parking because, while the column redirects the network, it consistently maintains network alignment with parking space, regardless of where the vehicle is headed.

Turning the net would cause it to invade adjacent parking spaces or, worse, traffic lanes (which is illegal if it’s also a chimney lane). The subsystem generates 25% more electrical power than a constant grid, and more electrical power means miles traveled or hours of operation of the appliance.

When it comes to transitioning to electrified construction equipment the biggest consideration isn’t the equipment’s capability, but rather, how to go about charging it.

In general, when the assignment of a structure is at the level where dirt moves, there is no electricity from the public grid on the site, or it is not enough to force the apparatus from the structure. The use of traditional solar panels attached to the desk to charge the device relates to some other structure assignment and would require more ground or invade the site. And the maximum sun installations only paint when they are hooked to the grid and the sun shines. There is no late rate or bad weather.

The EV ARC requires a small area (only one parking area) and no structure. It is delivered to the site, in working condition and moved to the next site as soon as it is no longer needed at first. Because it generates and retails all its own electricity, it can be recharged at any time, not just when the sun shines.

Because EV ARC is cellular and will be used and used in a wide variety of locations, it had to comply with appliance regulations and structural codes in any jurisdiction… most commonly everywhere. Therefore, the network may not be too large, even if you need as many photocells as possible.

Creating a giant table from subsets was as it added more complexity and longer setup/removal times. One solution is to fold the berry into a compact package for transport. But folding structures are sometimes not strong and uncompromising enough to cope with bad weather, especially wind and snow when deployed.

As any engineer knows, the weakest component of any chain is its weakest link. In the case of folding frames, they would be hinges. They must have been as strong as the other structures in the network.

The engineering team learned that the hinge only needed its maximum structural integrity when the network was deployed. The team then invented a hinge that is the maximum solid in the locked position, which means it is at full throttle when needed. When the board is packaged for travel, the hinges play a small role because the portrait rests on other elements. The packaged network can be seamlessly extended and blocked through an unmarried operator.

Most solar panels have spaces between the panels that allow the wind to pass freely through them while putting little pressure on the panel. For EV ARC, we didn’t have the luxury of dedicating part of the bay surface to the spaces; we had to maximize every square inch while we were convinced that it would face the upper winds.

Tightening, a strategy commonly used to mount modules on solar panels, uses tweezers in 4 locations, but this creates a single charge and can minimize the structural integrity of the matrix. EV ARC pliers cover the entire duration of each module, creating a beam. The patented application, called Envisimount, provides a full lifetime and increases the structural integrity of the matrix. The network has been officially cleaned and independently evaluated to cope with winds of up to 120 mph. We also know that it withstood category five hurricane winds of 18 to 5 km/h in the Caribbean.

It is no secret that, electrical or not, heavy slides require abundant power to counteract hatred. Typical diesel engine devices burn four to 16 gallons of fuel depending on the time, depending on the type of device and how it is used.

The new generation of electric equipment is relatively small and only consumes 10 to 12 kWh per operating hour. This presents a couple of issues, one of which is the intermittent nature of the sun as a power source. Obviously, it’s not always shining, which means sunlight is not always available to charge equipment.

This presents the need for a way to force the device when the sun is not outside. For us, the intermediary is the battery garage that we have in all our solar products. The solar-force garage allows us to take credit from each and every photon that impacts the grid.

EnvisionTrac moves the array to that it faces the sun during most of the day.Envision Solar

It is rare for a heavy-structure device to operate at full capacity for a full day of 8 hours. The service cycle is usually intermittent. According to popular industry figures, these devices generally operate at a fraction of their full capacity for 3 to 4 hours, adding time. There are outliers, of course, but understanding typical usage is important to expand a charging device that will work for genuine maximum – Global scenarios. Attempting to supply power for 8 hours of maximum capacity would result in significant overinvestment in the charging apparatus required for an all-electric fleet.

One of the benefits of electric machines is that no fuel is burned in idling. Conventional appliance machines consume up to 70% of their fuel in idle, creating heat, noise and destructive fumes. However, electrical machines consume battery power when in operation.

A typical small electric charger has approximately 40 kWh (kilowatt hours) capacity in the battery garage; an excavator of comparable length has about 20 kWh of garage. An ARC EV, which sells for about $60,000, can buy and generate enough electrical power to hold a charger with a lot of structure work, as the device recharges at the end of each shift and resumes in its entirety. In fact, structure crews don’t have to wait until the end of the shift. They can recharge it whenever not in use.

A loader or an excavator as described that gets plugged in any time it is not used throughout the shift could always be ready to work with a full charge, or close to it. Three EV ARCs can power two excavators and two loaders. If more capacity is needed, more EV ARCs would be deployed.

Envision Solar is now running on a wireless charging device that eliminates the need to connect it to the charger.

Desmond Wheatley is president and chief executive officer of Envision Solar.

By submitting this form and personal information, you understand and agree that the information provided here will be processed, stored and used to provide you with the requested services in accordance with Endeavor Business Media’s Terms of Service and Privacy Policy.

As of our services, you agree to obtain magazines, electronic newsletters and other communications about Endeavour Business Media’s related offers, its brands, affiliates and/or third parties in accordance with Endeavour’s privacy policy. Contact us by [email protected] or by mail to Endeavor Business Media, LLC, 331 54th Avenue N., Nashville, TN 37209.

You may opt out of receiving our communications at any time by sending an email to [email protected].

A vice president of Moog sees a long term connected and effective for the industry.

According to McKinsey and Company, peak primary structure projects are over budget and take 20% longer than expected. And the National Center for Construction Education and Research (NCCER) says more than 600,000 heavy appliance operators are needed in the United States as of December 2022. In other words, the structure can be an expensive and not easy task for your machines.

For example, the maximum structure device works all day, even when an operator waits between tasks. This results in higher emissions and fuel consumption because, even idling, a diesel engine runs a torque converter and pump. The advent of zero-emission devices can be a solution to some of the industry’s challenges. Countries such as Norway and corporations such as CASE Construction Equipment and Bobcat Company are among those targeting zero-emissions structure sites.

Last year, Oslo News promoted the first structure assignment in which all battery appliances reigned over the site. In Las Vegas last March, CASE introduced its backhoe, a first in the industry. And Bobcat, with its compact T76e track loader, has introduced the world’s first fully compact track loader.

Electric cars like that prevent as soon as an operator completes a function, so there is no power loss. There is also a relief in the noise. This means greater communication and noticeable improvement in the healthy environment of structure sites adjacent to communities.

Electrically structured appliances also reduce prices that are inconsistent with them. CASE, for example, claims that its 580 EV backhoe will save the owner up to 90% on vehicles, fuel and annual prices. By comparison, Equipment World magazine estimates that a 4-year, 4-year John Deere Model 310SJ backhoe consistent with approximately 900 hours consistent with the year would result in pre-emptive prices of $1,655 consistent with the year and $6.30 consistent with the diesel fuel time.

Battery generation is one of the drivers of the progression and adoption of electrically structured machines. According to BloombergNEF, an increase in the production of lithium-ion batteries over the more than 10 years has helped costs collapse by 85%, making electric cars commercially viable. Lithium-ion batteries allow longer uptime (up to 8 hours) for electric-structured cars and the ability to fully recharge some of those cars in 8 hours.

Our contribution to the progress of electric structure and zero-emission cars began two years ago through partnerships with corporations such as Bobcat, CASE and Green Machine to supply the engineArray device and the electric transmission solution called WhisperDrive. By offering software, exercise electronics and motors, wiring, gearboxes and devices, we helped Green Machine, which develops package systems to upgrade lead-acid batteries and fossil fuels, and Bobcat produced its T550 compact track loader demonstratifier and later its T76e prototype. Then we start running in the case of the old fashioned 580 EV shovel. And lately we use a variety of small hydraulic shovels.

The Bobcat T550 track loader we help expand is completely electric, so there are no hydraulic hoses or oil to maintain. With zero emissions, the T550 also gives the structure staff the opportunity to take the device inside a building. For the 580 EV, we partnered with CASE to expand a pump drive unit and traction formula, as well as sensors and lers that electronically control backhoe traction; loader and excavation movements are hydraulic.

Despite the emphasis on electrical innovation, hydraulic motion devices also offer the ability to integrate intelligent designs. In the future, with the right combination of sensors, controllers, valves, actuators and interfaces, a device designer can simply equip a structure vehicle that is helping its operator automatically detect unexcavated spaces, preventing a backhoe from digging with a safe intensity. or adjust. backhoe controls to a default slope.

With all that’s possible, it’s remarkable how happy classic device operators are still with the limitations and functionality of their vehicles. We know brands of devices and homeowners who have spent years adjusting and adjusting their appliances to make operators the best touch. As with the fit of a classic car playing with the engine controls and perhaps converting the camshaft, the mechanics adjust the hydraulic valves of a vehicle structure or replace parts of the joystick in the cab.

In our facilities, we have demonstrated how the right combination of controls and classic electronic devices for homeowners to digitally adjust their appliances, achieving in a matter of days what some appliance owners invest for years to achieve through mechanical adjustments.

The merit of digitally adjusting a vehicle structure is that owners can create operator-specific configurations for each user who manages the equipment. Using haptics is a way to make it less difficult for an operator to upgrade or operate equipment, as machine controls exchange data between the vehicle and the operator, offering a more accurate feel. The haptic, which comes from the Greek word “haptikos”, means a sense of touch. If you press an app on your cellular device, the vibration or sensation you feel is a type of haptic.

This sentiment might not be so vital for a veteran device operator. But as noted above, the structure industry has an increasing number of roles to play as heavy appliance operators. Making gadgets less difficult to use offers an imaginable way to fill those jobs with young personnel who gravitate around new technologies and games.

The fabric industry can gain great benefits from connectivity and virtual machines. Think about how 4G and 5G modems can structure controllers. By creating systems for structuring machines that come with appliances with a variety of sensors to monitor temperature, torque, existing and speed, operators are more efficient. By collecting this knowledge and downloading it to the cloud, owners of fabric appliances can analyze the output and replace the parameters through which their appliances reproduce tasks on the site.

Imagine an internet-connected power shovel that detects that your battery will be empty in two hours. The device then analyzes the weather forecast for the next business day rain. The device alerts your operator and its structure manager, and they adjust your power consumption to decrease an additional hour of work, but with less power, for a few more hours of clear skies.

Connectivity is not new, however, connecting devices, systems and appliances the right way (with built-in sensors) through new electric cars will make the task more efficient, safer and easier. In turn, what some might have idea becomes possible.

Ari Almqvist is the group’s vice president of growth and innovation at Moog Inc. Contact him at [email protected].

By submitting this form and its non-public form, you perceive and agree that the form provided herein will be processed, stored and used to provide you with the order in accordance with Endeavor Business Media’s terms of use and privacy policy.

As of our services, you agree to obtain magazines, electronic newsletters and other communications about Endeavour Business Media’s related offers, its brands, affiliates and/or third parties in accordance with Endeavour’s privacy policy. Contact us by [email protected] or by mail at Endeavor Business Media, LLC, 331 54th Avenue N., Nashville, TN 37209.

You may opt out of receiving our communications at any time by sending an email to [email protected].