CNC tools, whatever their flavor, can greatly be skilled for “manufacturing” or DIY. My current selection tool is a CNC router. Being familiar with a manual mill, the concept looked similar and the value of these is quite moderate compared to other tools. As described in this article, my device is a Zen Toolworks style, however, there are other features to scale in, such as this Probotix V90 style that was recently mentioned in this article.

While many CNC router models look wonderful in videos and images, be assured that even the most productive devices require a little patience to do a painting satisfactorily. Setting up your device can be a challenge as well as discovering what your device is capable of, but one thing that can slip into people’s minds is the software involved. Read on to find out everything you want to be informed of the basics of what’s happening in the scenes to produce engaging pieces with “magic”.

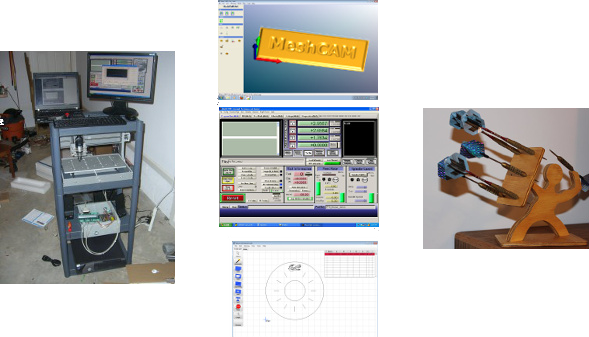

With a computer-managed CNC router (unlike a compromised controller), it has 3 parts in its tool chain: computer-aided design (CAO), computer-aided production (FAO), and a set of device controllers. There are loose versions and you pay for them.

The first step is to draw your piece. To generate the drawings in my room, I experimented with Inkscape, a vector graphics editor, and Draftsight, which is AutoCAD more or less flexible. Inkscape is a great program to generate more artistic pieces, like this random tree that I cut a while ago. If you need to do something more dimension-oriented, my favorite tool is Draftsight. I know AutoCAD very well and is available for Linux, Mac and Windows.

If you need to get into the 3-d design, Sketchup turns out to be pretty much the norm for creators/casual hackers/etc. Maybe I’ve been spoiled or brainwashed for several years running with Pro/E and Solidworks to a much lesser extent, as I found out Sketchup is frustrating. I think Pro/E (now I think) is frustrating, but I get paid for this frustration.

Whatever taste or design program you choose, if you’re familiar with the format, plan to spend a decent amount of time figuring out how to generate your parts.

G-Code, unlike some mid-90s rappers would make you believe, means General Code, and that’s what directly controls a CNC machine. You can write the G code by hand, and for very undeniable circles or lines, this can be useful. However, in most cases, G-Code is much less difficult to produce an FAO programme to translate its CAD style into this format. I tried several packages and they all have their pros and cons:

In addition to learning the software, you’ll want to know the kind of speed your device can really take care of and what it takes not to “plant” your device. Its CAM program is where it configures its advances, speeds, cutting intensity and other configurations.

Once your FAO program finally spits out several thousand lines of G-Code, it’s your device’s software that makes everything move. I use Mach3, which turns out to be a non-unusual program for recreational devices. Like everything else, it has a learning curve, but overall I’m quite satisfied with its performance.

One weakness I have encountered with this (and this is probably true for other programs) is that you want a genuine parallel port to work well (not a parallel USB adapter), and it is not designed to run on a computer as you won’t have any force control issues. I’m sure there are some solutions, but to save time, it may make sense to dust (or buy) an old computer to run it. It will work comfortably on replaced machines, so for about $150, you can have a PC running your router.

Another option would be LinuxCNC. When I first became interested in CNC, I hardly knew Linux. The challenge of combining a new operational formula with a new router was like a steep learning curve, so I didn’t revise that option. As I now use Ubuntu a lot, I may take another path today. If you have worked hard with LinuxCNC, please focus your reports by leaving a comment below.

To conclude, here are two CNC videos I made. The first is me burning a tiger’s foot, while the video of the moment is an instruction I did on how to engrave a logo with Inkscape. A CNC device is a wonderful addition to any store, but as I hope I have pointed out here, without its challenges!

Please note that, apart from this item, I have won special prizes and/or samples to be able to view products from corporations representing Zen Toolworks, Mach3, ESTLcam and MeshCAM.

Jeremy Cook is a mechanical engineer with a degree from Clemson University and is engaged in the production and automation of procedures. In addition, Jeremy is a passionate and former author of Hackaday. When you’re not in paintings or in the garage, you can locate it on Twitter @JeremySCook, your assignment blog JCoPro.net or on your DIYTripods.com photography blog.

What’s between a CNC router and a CNC milling machine?

Wood / Plastic vs Steel / Accurate.

The router is also 2d or 2.5d

2.5 D is a software restriction. THAT is, that is, I paint basically in 2.5 on my router because I only have the 2.5D CAM software. The device itself can paint in 3D.

I don’t know if there’s an “official” definition, however, I’d use a router to describe a suitable device to cut giant sheet shapes of plywood or MDF and mill anything that works on metal parts. Obviously, there’s some overlap there.

CNC Mill is a generic term that covers several categories of devices. A CNC router is technically also CNC milling. But to say that a device is a particular CNC router designates the pin mechanism. You can also make some other assumptions on CNC routers that are also true.

Routers tend to have high-speed pins and paints with giant blades. Often made of wood and plastic, but I saw advertising machines designed to take care of aluminum throughout the day.

Generators are derived from manual mills with controls attached to them. Modern CNC generators look very little like their ancestors. They’ll make all the curtains you can imagine, quite. Although other people’s wood is maximum.

Traditionally, a milling device moves the part to disarm, allowing the pin to remain still, while the pin in a more sensible motion moves and the part remains motionless. In addition, a mill is designed to cut metal, while a router is designed for wood/plastic. The effect is similar and, in fact, there are shared capabilities, but it’s another way to come to an end.

At least that’s what I think.

As Macona mentioned, the line is a little blurry with modern CNC device tools. Even my little amateur ZTW router is a type of hybrid; The bank moves in the Y direction, where the pin moves in the X and Z instructions.

A router is for 2D objects. a grinder processes the butter into three-dimensional pieces.

I’m sorry, I don’t think other people understood your question. A CNC router takes a sheet of flat curtains and cuts it into 2D or 3-d shapes (think of making panels, guitar bodies or cabinets). See YouTube for many examples. A CNC milling machine, on the other hand, transforms stocks. (Think about turning wood into a tower; generators are regularly used to make steel parts.)

In addition, there are other router models. Some have designs where the paint room remains tied to the desk and the router moves on a porch. Others, the piece to be disassembled moves on a table and the most sensitive head remains constant (less popular). Crushers and routers can cut many wood fabrics, metals, plastics, etc. with the right strands, cutting harder metals is very complicated for a milling head. Routers can be Fixes … Well, run genuine wooden routers or some other people have been updated and have chosen to place pins on your device (almost the same configuration, but the engine is designed to run for long periods without damage. .)

In short, clarifying what others say, the type of curtains or how it cuts the curtains, is not what differentiates the router from the shredder. It is the configuration (mainly) and its capabilities. Router: Flat inventory mendacity down (unless we talk about five routers, then think about automated sculpting capabilities) and milling: part filming.

You’re confusing the challenge here. With a CNC milling machine, the room is enclosed in a desk as the cutter moves, in the case of 4/5-axis machining centers, where the component also moves relative to the cutter.

CNC tower, the component rotates while the cutting tool is basically stationary.

I know it’s making a dent, but I’ve worked in CNC machining for 20 years.

No… it’s a CNC tower. A CNC milling machine rotates the bit like a manual milling machine … simply computer-controlled.

blah, blah: no interest

Then why the hell did you write this page and even review?

@John: Perhaps the CNC router is only for wood, while the CNC milling machine can cut any material?

There is also Heeks CNC, which produces G code. It has limitations and crashes, but it’s still quite useful.

I’m an amateur CNC explorer. Yes, there’s a learning curve, but part of the laughter is learning, so I appreciate that part of it.

My CAD/CAM is BobCAD. It is difficult to learn, but it does the job for both OAC and FAO. I bought a used edition on eBay and it works well. It has 2D and 3-d functions for full 3D engraving or cutting.

Mach3 is fine, but my PC crashes from time to time, even after removing most of the causes.

My CNC machines are changed the Sieg (3D) and Enco (2D) knee pads. You can buy anything from Zenbot in Tormach, depending on your wishes and budget.

Unless technically, I would propose to buy anything commercially, or anything from Craigslist that responds to your budget, and then update it or create one yourself later. Addressing the CAD structure, FAO, integration, PC, CNC at the same time can be intimidating.

This hobby can be useful: I cut aluminum quadcopter legs that are no longer manufactured.

Good luck.

Hackaday Rocks.

I have two sets of tools. To route remote PCB lines: Eagle – pcb-gcode (with self-leveler) – LinuxCNC and for wood (and some plastic) Sketchup – SketchUCam – LinuxCNC.

How’s this a trick? Although I see the price of having guides like this on the Internet, that’s not the explanation why I come to hacked. I’ve noticed many more publications like this lately. I’m not saying they’re not smart material, but that’s not why I come here.

Everything is fine. I’m not saying it’s a bad thing, but after the new owners have taken over, I see more and more editorials, fewer and fewer genuine tricks.

Yes, I noticed the difference. I love it. There are still many attractive projects, but the combination is different. As what I’m looking for is the inspiration for my own projects and the ability to be informed of new things (for me), I’m very happy. For others, perhaps a clear “cheats only” would be a smart thing to do. Sounds like an undeniable trick! 😉

This is to create tricks, have you complained about articles about refusion welding techniques?

Overall, the new more balanced part combination. Follow.

1 linux cnc

Anyone contemplating using Mach3 deserves to get part of the story directly from the horse’s mouth, so to speak. Search for “The Mach3 Add-on Writers’ Bible through Art Fenerty” to see how exciting this is. Figuring out precisely what happened to Mr. Art Fenerty can also be an attractive exercise. Some say he retired, others say he disappeared like a thief at night. His departure was brutal, that’s for sure.

There’s something rotten about this. However, also note that Mach3 and LinuxCNC are based on the same NIST code base. A guy went in one direction and the team went into The Array

Now, if after all this, you are still seriously considering a Windows app for controlling critical devices, you deserve to seek professional mental help. Because you’re crazy!

Mach3’s challenge is not that it works on Windows. The challenge is that free software of choice (EMC2) is much less difficult to set up and use. I have Mach3 on a CD provided with the engine driver. I gave up despite the commands and screenshots provided with the controller. Then I installed LinuxCNC with EMC2, set it up, and started it without any challenge.

I don’t agree with Windows. I have multimillion-dollar hardware from a Windows 7 PC at work, and it runs for weeks without problems. Yes, Windows 95 wasn’t reliable, but that was a long time ago.

Don’t do it with the facet of genuine time. Actually, I don’t know Mach3, but Windows and the original time aren’t the most productive friends. I think other people have been executing expensive things to get commercial answers that download things on a controller committed to some brains.

But for the average user with Mach3 on a desktop computer … I think the lack of genuine time is a major disadvantage of LinuxCNC. In this sense, the challenge is that it runs Windows that does not have comparable original time add-ons like RTAI, Xenomai or even RT-PREEMPT.

Real-time things become less and less vital as motion controllers become more common.

These execute the code g; not mach3 or LinuxCNC, etc; and are connected to the USB or Ethernet PC. The actual time is only for the parallel port, which may eventually disappear.

Motion controllers will never be as unusual as PC surpluses are now. Your parallel port claims are also due to several reasons. First, you can put a parallel port on any PC with an open location. You can also use other types of IoT cards for real-time publishing.

We have a $1.3 million 5-axis mill in paints that runs on windows like some 4-axis mills, a beloved punch and a bystronic laser that moves at a crazy speed.

Does the device itself run Windows? I know that Windows 7 works on the computers in our workshop, but they only move the program to the Mazatrol driver of the device, which is running Windows.

Yes, they have windows. Makino Mag 1 and two Makino A82, Amada EM2510 and a Bystronic BySpeed 3015. All windows run as software.

He used to fix CNC plasma cutting devices for Airgas and Hypertherm also used Windows XP in its CNC controls.

There are real-time extensions for Windows that will work as a real-time Linux kernel.

even MACH3 will have to use special real-time deception controllers, there’s no way a “normal” win32 program can spit out consistent pulses on a parallel port

Yes, use some tricks to capture the parallel port directly from what I understand. There’s more data there yet, I never bothered because it doesn’t matter as long as it works. It was never the pulse that caused me genuine problems, those are other software problems.

After consulting the documentation, they configured a Windows-like interface in the driver. There’s no way the API will save your scenes.

Then they also installed a Windows XP home screen.

It is not a PLC, a device controller, like a PLC with steroids.

-Flow- logo waterjet cnc also runs on win7 … Fix the amazing device to make it work…

Oh, and our Mazak Integrex 1060V-II uses windows in the command and the “e-tower” that supports it.

You may be running a built-in edition of Windows. Same code base as ordinary Windows for desktops and laptops, but it has a formula that will surely customize the installation so that it only has the surely required parts for the formula in which it will be used. XP Embedded is still used very frequently, Microsoft made an update in 2009 that was still quite XP-based before releasing the next Windows 7-based edition (IIRC).

AFAIK, the only time Windows was used integrated on a client PC was Dell Media Direct (up to issue 3.5) on some of its laptops. With edition 2.0, it has been installed in the protected area of the host, it can also be installed on a general hidden partition on non-original hard disks. DMD 3.0 to 3.5 used the reinstallation partition scheme of previous editions by default. After 3.5, Dell left the special partition and Windows Embedded, making Media Direct an undeniable multimedia program running Windows in general.

Windows Embedded enabled faster loading of Windows and the ability to run general Windows media software, unlike the schema used through Hewlett Packard running a traditional Linux edition for its quick-start CD and DVD playback mode.

On a CNC machine, it would be imaginable to create a special onboard Windows installation without more luggage and with special controllers for real-time control of the machine control equipment.

Mach 3 has its own parallel port controller, which I guess does some things like that. Contrary to popular belief, it is imaginable to do anything with the parallel port that was imaginable with Windows 9x or DOS. Mustek was one of the first corporations to produce this when Windows 2000 (and later XP) drivers were released for the maximum parallel port scanners they had manufactured, adding many abandoned models.

Meanwhile, UMAX has defected from all its parallel port scanners, claiming that it is “impossible” to use a parallel port for Windows 2000 and XP analysis. A moment after Mustek did the “impossible”, UMAX released 2000 and XP drivers for some of its parallel port scanners.

Declaring that anything is “impossible” to do in Windows simply means you can’t figure out how to do it or just don’t need to verify it.

I maintain that it is about legally publishing the kernel source code for Windows so that everyone can freely review and modify it. Now show me how you can figure out how to do this.

It’s very simple to do. Simply purchase all the necessary rights to do so. There is no option or difficulty, only cost.

FWIW, Prototrak SMX loops run in real time on an XP installation.

That’s completely correct. I have prototrak and run Windows embedded. W xp is a real-time solution

In fact, prototrak can work in original time on any edition of Windows. Including x editions from 9x to 10. There are execution times to take over parallel and genuine-time communications ports in win32 that have been around for years.

Why is this so off topic?

My experience is graphic design. When I started searching for CNC drawing programs, I made the link that Adobe Illustrator can export files. DXF and. Dwg. For me, Illustrator is the fastest/simplest program for creating complex shapes, aligning shapes and nesting parts.

I’m also a big fan of V-Carve Pro. It’s expensive, but I think it’s incredibly resilient software that’s helping you make the most of the learning curve.

I seem to have heard some clever things about V-Carve Pro. I didn’t know That Adobe Illustrator could simply produce DXF; It’s an attractive feature!

I have a legal copy of vcarve pro, but I kicked it out of your forum without caution when I posted a message asking for problems with the tool trail. They don’t like users posting “errors”. Especially if backup documents are included on the screen.

How does LInuxCNC work with fashionable machines? In other words, Mach III is limited to Windows XP, it will not work (very well) with newer operating systems/machines. Mainly because fashionable appliances treat the parallel port of older machines.

Your query is a bit complicated to respond because LinuxCNC is an open source project. As there is no cut or drying, this is the last code that can respond. You can create RTAI kernel extensions in a highly updated kernel edition and run it with LinuxCNC code.

Certainly, the LinuxCNC ISO symbol is quite replaced today. Personally, I don’t use it. I did my last build on Debian Squeeze, but I’m looking for something compatible, not necessarily the last or most productive I can have. Also, Ubuntu only makes me need to throw up, but it’s a totally different matter.

The strength of loose open source is the freedom it gives you. I also take full credit for this with LinuxCNC. I almost made LinuxCNC paintings on Gentoo, but succeeding in doing so is a real whore. Knowing what I know today if I gave him another chance, he probably would. I had a hard-to-understand challenge to which I’ve discovered the answer that stopped me last time.

I get pretty crazy latency scores on Gentoo. About 1750 nanoseconds. I only used an older AMD X2 processor.

Mach3 works on Win7.

I don’t know anything about Win8.

Define well.

The key to compatibility is to stick to the same binary edition of the operating system. Some 32-bit systems may not work on Win7 x64. I discovered that this was the case with Epson’s scanning software. You may not connect to the scanner via the Win7 x64 USB port, but it works well on 32-bit Win7.

So, if you need problems with your 32-bit hardware, stick to the 32-bit edition of Windows.

Another ‘1’ for LinuxCNC. In reaction to “will it painting”, the answer is yes, it will do anything, adding complex joints like delta robots, SCARA and Stewart platforms, with caveats. It is up to the user to be informed of the system, then reconfigure the INI and HAL (and ClassicLadder if that’s the address they chose) for their application.

LinuxCNC is an incredibly physically powerful and underutilized platform, in my humble opinion, and its perspective is wasted by the fact that the little documentation that exists is difficult to understand to the extreme. That said, I took the trouble to be informed of Linux just to be able to use LinuxCNC effectively…

See my website for some examples of HAL and INI files

You, sir, know how to recommend websites; please chorus to do it.

Chico will be your red face when you realize that you simply click on his call to his website.

And you, sir, are equivalent in ignorance.

The correct way to recommend a link is to place a link to the post with the URL of the same displayed as text.

No one will intuitively think that if I just click on the boy’s call, I’ll be redirected to his Matrix. Most people will assume that clicking on the boy’s call will take you to their profile page where their comment is posted and is typical. of s.

Another option for CAD and FAO is TurboCNC with the CAM add-on, you can get previous versions for less than $100 on eBay and it’s a very smart package. We taught it and used it in TechShop when we were still there.

I’m using LinuxCNC for the first time in my current project, a 400W laser welder. I want it because I want a lot of I/O to the laser. Making some things look good on Linux has been a PITA.

none of that, I looked

Argh, it was TurboCAD. Not TurboCNC.

Mach3 comes with a perfect set of instructional videos to get you started. They are very useful and advise you on the process. http://www.machsupport.com/videos/

He understood this, what I should mention is that LinuxCNC is easy to use and works very well.

Did I mention it’s loose and easy to use?

I’m glad you enjoyed the article! The answers make me need to review LinuxCNCArray ..

It’s as undeniable as getting the ISO symbol and starting it. You don’t even want to install LinuxCNC to run it. LinuxCNC works live. You can connect linuxCNC and let’s go. The most productive LinuxCNC installations do not use hard drives at all. Because business environments can be difficult, many use a CF card. But to run a live session, you can use a USB stick.

Bizarrely, I can’t locate any smart commands on the network to know how to proceed. If it were me, I would download ISO and then use atbootin to write the symbol to the flash drive. The LinuxCNC ISO is based on Ubuntu, but it’s not exactly Ubuntu, so generic Ubuntu commands wouldn’t work. Choose the ISO symbol option in atbootin. I just checked and LinuxCNC is not a menu item.

Some LinuxCNC users and developers hang out in #linuxcnc in chat.freenode.net. You can ask them if you’re stuck.

That’s great. Thanks for the advice!

It’s simple, I installed my device at 18 and discovered it simple at that time. Simply locate an abandoned Pentium four PC, insert the disc you’ve recorded, and within an hour of your walk, you deserve to have it in one position for use.

I’ve heard that P4s are not effective in real time. I have one, but I’ve never compared it. For a while, I was a P3, and it’s a little horrible. I run about 18, 500ns with him. Now I have an AMD X2 at 2.5 GHz and can score around 7500ns. It’s not bad to contemplate that I only paid $5 for it. If I had to buy a new one, I’d go with an Intel Atom. They’re the most productive price for money.

Latency scores are fun. The most productive action PCs are not the lowest latency machines. Real-time latency is not something that PC users sometimes master. It’s not a specification that’s actually published by Tom’s Drapery.

Here is a chart that should be taken with a grain of salt, because many of them do not know how to configure the software optimally. Knowing what you’re doing can make a big difference.

http://wiki.linuxcnc.org/cgi-bin/wiki.pl?Latency-Test

But this can give you an idea of what the hardware can do. The time and time column is the maximum for steppers. The lower, the better, of course.

Well, if you found out simple at 18, you’re doing better than I :). This is how you can use older systems with CNC projects. My first PC ended up laughing at me, but what I paid for it, I wasn’t too angry.

LinuxCNC would possibly work on older systems, but would possibly delight in a drop in performance. I could only achieve a latency of 18,500 ns on a P3 1 GHz on which LinuxCNC is installed, which is not exceptional. This device also cannot run the Axis front line because of the graphics card it contains. Something with this video card and any GL program could cause horrible latency spikes.

Later I was able to get an AMD X2 at 2.5 GHz and it works much better.

I have a mini mill equipped with a mach3 preset PC that I have used for about 2 months. Then I tried linuxcnc and used it for four months. As I used either program, let me start this article with a smart list.

My mill came here with a PC with Mach3 all set up, so I can use it, but I had many disorders with it. I’m pretty sure the disorders came here from Windows, not from mach3, because the disorders were on the pc scale, not just mach3. I made the decision to try linuxCNC instead of fixing the Windows installation, because in my experience, Linux can do wonders for the old sexists and was right! on the same PC, Linuxcnc made all my hardware problems disappear, and it was up and running in an afternoon. Now I say that the easiest graphical interface (graphical user interface, the screen you see with all the yettons when you open a program) was greater for me than Mach3 because I had to search or load purposes that I sought to use, and the ones I didn’t use were not shown/hidden. In Mach3, there are many yettons and some have misleading names. Infrequently I notice that the yettons do not do what I thought I would do, or that the settings that were activated are actually disabled because I have no idea something about the yetton (color, shading, etc.) which meant it was turned on, but that literally wasn’t the case. At linuxCNC, since I would like to set up such a thing, I would be forced to be a little more informed about it and avoid making stupid assumptions. informal silly evidence if you will. It’s not literally a Mach3 flaw, but a flaw of mine, however, is an opinion piece! On the load, the linuxcnc forums are full of literally intelligent people who have helped me enormously. a user has created a loose magic tool that will take the exported Mach3 configurations and turn them into linuxCNC configurations that can be imported, making tips much less difficult. I also like the fact that using the gcode of linuxCNC, etc. is much more documented and less difficult to perceive than Mach3, it turns out that there is much more data on the Internet so that the informal reader can dig deeper and find out how to do what they want to do.

Well, this article was hand-delivered, but once I started writing, I learned how much I would have liked that if I’d known about that before, so I felt a desire to keep writing. I started “wishing” to know the g code when I started using prisners 3-d about 3 years ago (I built 2 so far!). Although in 3-d printing, you go directly from one style to another, you never look or think of g-code, only in the gcode generator. I have been using my MIll CNC for a few months and I love it, but I already want a bigger and faster one. Especially only bigger though. For the purposes of the above, I am a mechanical engineer and machinist, I have not been paid through anyone for this position and I have no association, besides being a maximum user of the previous software. However, hack-a-day can send me a check with this information. I have a lot more if you want a follow-up;

Oh, I guess I deserve to do a brief presentation on the hardware, even if it’s a software article. In fact, you don’t want a fast and modern computer to do everything you want to run your machine. This will help cad things, because CAD packets can actually work on a PC, but for genuine G-code execution, the maximum all speed processors will work, even a PII I’ve heard of well. It’s not the speed of the PC that counts, but “latency” is a very fast way to measure speed. It is VERY DIFFICULT / IMPOSIBLE to be waiting for the latency of a pc according to its expressions. The good news is that you can verify your latency by using an Ubuntu LiveCD with linuxCNC pre-installed. Lots of data about him on the Internet for you. However, you want a genuine parallel port on your PC. The easiest way is to order online/search forums for PCs that other people already use and just copy what they have. There was a combination of Atom mobo/cpu that does not take long and that other people still have in the inventory, which was a reasonable and popular option, again, the data is available. A great tip I have is to get a graphics card, ALL graphics cards and their latency can greatly improve, so my PC 12 years or older now looks enthusiastically my factory. Another option is beagleboarding. I would have bought one without delay if I had known what it was when I bought 2 raspis to learn Array, the hardware moves very slowly in this world, so the parallel ports are still god, many things happen through them, or especially designed PCI / PCIe cards (see table, but even after employing CNC stuff for some time, browsing their site, I remain, I can’t understand what I look at …) so it’s very simple to expand… CEPENDIENT, do not be fooled as I did, I think “hey, my repetitions use arduinos, I bet that in the long run I can give up the PC and have an arduino and a raspi hidden under my bench of paintings”, but no. I guess CNC machining uses the full force of the g code a little more than currently a reprap does, and will concentrate on a raspi at its limits and an arduino is simply not up to the task. But with the maximum of you, nerds, in the backroom with at least 20 “too old to do something useful” machines, why worry, you probably already have the box you want for a CNC. Save this money and speed up on a touch screen.

This is piracy!

Kidding. Thank you, data collection on the maximum intimidating domain of the home CNC: the software.

Thank you for your knowledge! I have a half-built shapeoko here, so I couldn’t have come at a better time.

You’ve forgotten these

http://wiki.linuxcnc.org/cgi-bin/wiki.pl?Simple_LinuxCNC_G-Code_Generators

And that

http://www.linuxcnc.org/docs/2.4/html/gui_image-to-gcode.html

I tried many CAD systems, but the learning curve has been a challenge for me, I discovered Delta Cad in deltacad.com and discovered it less difficult than the maximum CAD systems, I also discovered Cut2D in vectric.com easy to use to convert CAD files into GCode.

It bothers me that the article doesn’t perceive why a parallel port is so critical (or some kind of genuine hardware connection … table card). It’s !!!!!! latency You cannot run a procedure in real time via USB. Not to mention a PP to USB adapter. This tells me that I have never built one of these machines before and does not perceive the underlying concepts.

I used MeshCAM. At first, the interface looked great. After handling it for a while, I discovered that it lacked functions and had errors. Finish editing a lot of gcode before it is usable. But it’s only $250 and I want the cam package features of $1,000-2,000. So it’s a set of expectations and features.

LinuxCNC is THE way to go. I have a LinuxCNC 3-axis mill. I’m starting in a bigger factory. Basic configurations are easy to configure, however, once you make adjustments and customizations, the learning curve becomes very steep. But LinuxCNC is so powerful. I think some OEMs use LinuxCNC and just disguise the property with the interface.

Hello, thank you so much for Mesa Electronics! They LinuxCNC as soon as it comes out of the box. They’re unconditional superhackers.

Your delight with the keys in linuxcnc looks precisely like the kind of things you can customize in the package. Changing keyboard shortcuts is quite basic.

That said, you’re in luck. I’m trapped in a proprietary land with a CNC Next Wave automation shark. I would love to customize the fundamental functions: the software works well, but the user interface is very rudimentary. The USB box only works with its very limited software. And the software requires a registry key even though it only works with your hardware. They say it’s to protect yourself from the use of stolen devices, but it doesn’t make sense. In the coming years, I hope the device is a brick due to the lack of registry keys. They are not willing to allow mach3 or any alternative. The user must be verified!

I spent hours looking to run Mach3 on my home-built CNC machine. I couldn’t even move an engine one step.

With linuxCNC, I made it paints in about five minutes.

CATIA is approximately 20 times larger than its little brother’s SolidWorks CAD program, and can also make FAO. While the full ad will charge you $30,000 according to the seat the last time I looked at, the student edition costs less than £90. Model in 3-d and then export 2D according to the perspectives in dxf format from draft mode.

I guess AutoCAD has replaced a little, it’s terrible for anything other than 2D.

This is also my pleasure with AutoCAD in 3-d (although I have not tried to extrude anything through it for some time). For the ultimate things I do at home, a 2D drawing works well.

I’ve never used CATIA, I haven’t even been exposed to it. I hear rumors that engineers are running, but most of the things I contact are done with ProE, Solidworks or AutoCAD.

no amateur can CATIA.

About three years ago, I pulled a computer out of the dumpster to play with it. There were two challenges. 1: One of the cooling fan brackets is broken. adding a zipped tie and this challenge has been solved. 2. The CD player was locked and closed, which was temporarily resolved with a clip. There is a CD set to boot.

The next thing I did was install Windows 7 32-bit. Once I had my bluuMax setup, I installed Mach3 and did some tests. Once I had the wiring and everything well installed, Mach3 worked very well.

Then I installed LinuxCNC in a dual boot configuration. LinuxCNC works very well.

Based on the disorders that other people posted here, I had to be lucky with my setup.

A clip and a tie? I think you have McGyver’s talent.

accidentally on purpose. 🙂

Has anyone experienced using an exclusive and simple motion controller (GRBL or similar)? Do you have any advice or advantage/disadvantage compared to a device driver on the PC?

I look forward to controllers like smoothieboard /4pi- fully autonomous once you have started milling paints (send the USB/Ethernet log and it will be stored on the SD card). But it’s a more expensive and non-counterfeit order of magnitude at this point.

RPi – Octoprint?

Please help … I can only install BobCAD-CAM on one device and save a copy to a portable hard drive. My CNC (plasma) is connected to your own replaced computer in the store. I prefer to paint in BobCAD on my computer. Is it imaginable to get BobCAD G codes on my computer to my CNC in the workshop with a flash drive, disk or email? Or do I want to install BobCAD on the PC to which my CNC is connected?

Thanks a lot!

Curious agriculture teacher

I just looked at the online page and felt like I was going to hit my head with the banner on the most sensitive part of the page and that doesn’t refer to the text that’s so close to the back of the banner and that goes underneath that. I feel like I’m hiding something. Then there’s this annoying link that is in a position where it’s right above the text and still gave me the impression that they were hiding something.

This is the biggest challenge with exclusive PC programs that have features. One computer is better as a driver while the other is better for processing CAD files and generating g code. The store setup may not be as convenient as the settings you have in your office.

You can check the installation of BobCad on an external player as you would With PortableApps. You can then move the unit back and forth. Design on your laptop, move the unit to the workshop, and run the CNC.

It depends on the PC of your store. If you run WinXP, you deserve to be able to do so.

You do not want to be informed of Linux to use Linux CNC. Simply follow your installation commands (you will need to have a smart CD-ROM or it will throw your PC away). Complete the installation, start again, and wait to see the desktop. Then the program begins. If you want to make new PCBs, read this and play with linuxcnc.

The maximum vital component of the linuxCNC configuration is to adjust its configuration with the instruction manual of your CNC (and the schematic): open the LPT port (what does the pin do? Input? What proximity sensor goes to where? How many steps consistent with millimeter does it have? shaft motor (see CNC manual). Save your settings in “My Mill” or whatever.

I use my CNC – High-Z S / 1000T without remote sensors activated and without automatic control of pin on / stop. I adjust everything manually as in the days of the TNC Pleistocene: X and Y are reduced to 0 after moving the tool only my eyes and a strong soft flash as a reference.

The Z axis is calibrate by reducing the speed of the stepper motor to 12 mm/minute and a small piece of newspaper between the milling tool and the PCB surface. When the newspaper sheet can move slightly, the tool is in a working position.

I use CadSoft Eagle with its command “run pcb-gcode-setup”. There I set the milling intensity to -0.075 mm and the Z-down to -0.075 mm. Other changes relate to the tool length (usually 0.1 mm for SMD parts), the speed in the 3 axes … And that would be it.

I agree with LinuxCNC because MS Windows is not, and has never been, a real-time operating system. Only UNIX, Linux, and BSD fall into the category of real-time operating systems.

If you are concerned about the CNC, Linux will not be so complicated to use for you.

Hi guys, what cnc device do you think is to make a smoking pipe with a block of 10x7x5cmm wood?

You don’t want a CNC. Use a drill, get concepts from YouTube videos from How It’s Made. These things were done for many years before CNC

All done before the CNC. The type can use the CNC to make a hose if you want. If you don’t know the answer, don’t be a D! CK and give him B.S. You’re an idiot.

I have to say mach3 is just a bunch of smoking shit. It’s a software with such amazing bugs that it destroys things day after day just because they’re insects that lead you to a central attack. Example, the last time I had to pause my work, set the next starting point to several millimeters. After that, the feeding rate increased from two hundred to 2500. Etc. In the last four days, he had destroyed things about 10 times due to such insects.

Try HSMWorks, it’s built into Solidworks and Inventor. If you don’t have one, check the Internet version of Fusion 360.

http://cam.autodesk.com/

Hello, I have a cnc teetz z100 router and the packaged manual driver, will I have to use the mach3 software to run and configure the machine? Thank you

I have a Mac. Is there any FAO software available or smart that everyone knows about?

To make PCBs, see FlatCAM (http://flatcam.org). Works on Windows, Linux and OS-X. Oh! And it’s open source!

By the way, I’d like to because of my ignorance from the beginning. Thank you for taking the time of a beginner.

Do you still have those discounts for the software? I just bought a CNC and worked with MakerCam and a universal g-code transmitter, but I’d like to see MeshCam and Mach3.

In fact, I’m also in favor of the same thing. We also want to check your other precision parameters by opting for the CNC router because in some cases we want longer tables for longer work.

I’m about to buy a CNC router and wonder if it’s possible to scan a symbol and then turn that photo into gcodes. New to that and I was looking. Thank you.

Suppose the drawings I have are several PDF pages but they are scaled. Do any of these CAD systems or software convert PDF sections into drawings that can be used as templates? If so, what are they?

I use a Mach3 program to work, it’s very and massive. G-kod do in Solidworks

Can I use a crack autocad and then use the drawing on a CNC machine?

Why didn’t you mention mastercam?

Hello everyone, have access to many weeks and think that maybe you’ll even invest in one. But, before I make that leap, the number one consultation I’m doing is. What is the legislation regarding the use of systems already drafted to manufacture a product for profit ???? I can’t find a transparent answer. I know there are many other people floating there, I just bought 15,000 dxf files for $20. But the legality of it, can you tell me?

it’s a little useful a little vague. received a DIY CNC device that works with manual control. you want a cnc program that works well with an Arduino.

I tried Mach 3 on a router many years ago. It worked well, but it broke in half, ruining the project.

LinuxCNC works very well and can be highly customized, if you don’t have your mind set on learning.

Alternative to mach and linuxcnc

http://www.centroidcnc.com/centroid_diy/acorn_cnc_controller.html

I bought a reasonable CNC 3018 on eBay and use estlcam to import/export designs and card/CNC. I chose the mach 3 device preset to flash on the card and makes the CNC paints but the drawings go crooked, i.e. too wide, not high enough, etc. I wonder if any other preset would be more oriented by the reasonable table I have. Or is there any other card you can get that would make CNC paints better? Actually, anything you can tell me about all this would be useful!

A lot of programming is required for the machines to function properly. With manual milling, you don’t have to worry about programming or the time it takes to make sure the main points are correct.