First design

Site theme

Sign up or log in to sign up for discussions!

When desktop processors first crossed the Gigahertz level, it seemed for a while that there was still nowhere to go. But the progression of the clock speed eventually stopped, not because of the speed itself, but because of the force needs and the heat generated through all that energy. Even with the now-usual enthusiasts and large heat sinks, along with sporadic water cooling, heat is still a limiting thing that speeds up today’s processors.

Part of the challenge with liquid cooling responses is that they are limited because they will first have to drain the heat from the chip and feed it into the water, which has led some researchers to consider passing the liquid through the chip itself. Some Swiss researchers have designed the chip and the cooling formula as a single unit, with liquid channels in the chip positioned next to the parts of the chip. The effects are an impressive improvement in heat-limited performance.

Part of our challenge in extracting heat from a chip is that it regularly involves multiple connections: from the chip to the chip package and from the chip package to a heat sink. While steps can be taken to improve those connections, they are inefficient, which adds to restricting the warmth we can extract from the chip. This is true for liquid cooling systems in use today, which use the liquid to reposition the steel heat sink. Although it is conceivable to place the chip directly in a heat-conducting liquid, this liquid will have to be an insulator and not go through chemical reactions with the electronic parts, two obstacles that water cannot remove.

There have been a number of demonstrations of liquid cooling on chips. It is a formula in which a device with a set of liquid channels is fused into a chip and a formula pumps fluid through it. This can take the warmth out of the chip, and initial implementations found there was a small trade-off: It takes more force to pump water through those channels than it is squeezed out of the processor. This force is not used in the place where heat is a problem, so it does not interfere with heat dissipation, but it does decrease the force power of the formula.

The new studies build on these concepts to increase the power of on-chip cooling systems. And interested researchers show that it works using a force conversion chip that would reduce functionality in a different way through heat.

The semiconductors used for force conversion responsibilities are sometimes not silicon. Instead, gallium nitride (GaN) is typically the pick because it handles higher frequencies and reaches higher frequencies. However, to maintain compatibility with existing production approaches, maximum GaN devices are built on the maximum sensitivity of a silicon wafer, providing only physical material rather than contributing to the circuit. For the researchers, the silicon provided an opportunity: we know how to control its design at an incredibly fine scale, which can be used to position the coolant channels right opposite the surface of the GaN circuits.

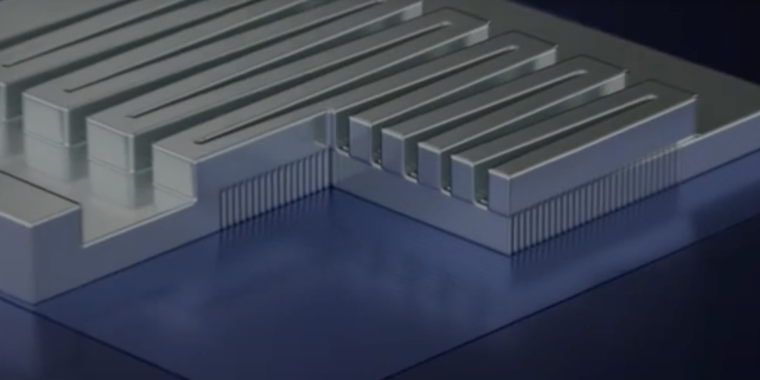

The structure procedure is elaborate. Incredibly thin grooves are initially cut through the GaN and into the underlying silicon. Then an etching procedure that affects only silicon is used to widen them into channels, the original spaces through the GaN layer are sealed with copper, which improves thermal conduction. Beneath those channels is a set of alternating passages that they act as feeders and wells. The cold water enters through a feeder, circulates through the channel where it captures the heat and is then sucked into a nearby sump.

Researchers are organizing things so that the parts of the device’s GaN component are placed very close to one of the channels, which is consistent with allowing for more effective heat extraction. Many articles involve testing other element geometries such as channel width and spacing. All the time, the researchers tested the amount of energy needed to force water through the system, which also put some other pressure on the geometry. The most productive design they discovered is capable of handling heat flows of up to 1,700 watts consistent with one square centimeter while restricting the constant temperature increase of the chip to 60oC.

To turn these studies into a usable device, the team used a thick, double-sided adhesive layer and cut channels with a laser; The chip was then glued to this adhesive, the water was pumped into the adhesive, from where it flowed into the chip, all this packaged in a popular electronic card, with wires connecting it to force resources and valves used to force system water.

With the formula in operation, the constant temperature would only increase by about one-third degree Celsius for every watt of force it handled. With a heat tolerance buildup of 60oC, that meant the device could only extract 176 watts while requiring water of less than one milliliter depending on the second. In addition, by keeping the heat limited, the circuit consistent with formed its force conversion more efficiently.

What can be the size? The authors cite estimates that about 30% of the average force intake of knowledge is spent on cooling and that they use about one hundred billion liters of water per year. If you can follow this generation on all chips, not just force converters, it may only force you to cool to less than one% of your existing values.

But we are very far from that. For one thing, the researchers chose something incredibly undeniable to verify their formula, which helped them design a cooling formula that aligns with the hot spots on the chip. Anything more confusing than that, and organizing the lineup can be significantly more difficult. This is especially true for general-purpose processors, where used chip parts can be replaced depending on workloads. The formula will also want to be checked for long-term stability, making sure its presence causes structural defects and that the interaction of high-temperature water with copper, silicon, and GaN causes unforeseen problems.

Finally, there is a possibility that water resources and wells, various (power, GPU, procedure or), all at the right pressures will be integrated, so we are far from seeing this accumulation in any hardware, but at least it is great to see it. a demonstration that the procedure can be performed effectively.

Nature, 2020. DOI: 10. 1038 / s41586-020-2666-1 (About DOIs).

Join the Ars Orbital Transmission email for weekly updates in your inbox.