The strain to become greener and more sustainable in operational terms is a primary attention for fashion brands. It is a key component of your Corporate Social Responsibility (CSR) model. Consumer behavior is also driving brands to take sustainability seriously. An exam conducted through YouGov for Doddle, a collection and click service provider, found that 43% of UK shoppers would likely buy from a rival store if they had a wider range of sustainable delivery options.

The emergence of new environmental regulations increases the pressure on industrialists. The extension of the law on the use of chemicals is a good example. Halogen-free production processes are vital as new regulations come into play. IEC resolution 61249-2-21 of the International Electrochemical Commission (IEC) established popularity in this regard.

In the long term, water use in the surrounding production would possibly even be affected. Deionized water is already essential for medical, electronic and food production. Since environmental problems are unlikely to disappear from the legislative agenda, trademarks will need to prepare for long-term regulation.

E-waste management

One of the demanding situations that most attracts the attention of brands is to locate tactics to reduce the electrical and electronic waste (electronic waste) generated through their activities. The amount of e-waste created worldwide is developing rapidly: worldwide, the total volume is expected to succeed in around 7 kilograms of e-waste in line with the capita by 2022.

At the production level, we are seeing a greater concentration on reducing this waste. One way to achieve this relief is to ensure that the parts of the finished products and the new technological responses provided to the source chain are completely reworkable and can be repaired without problems.

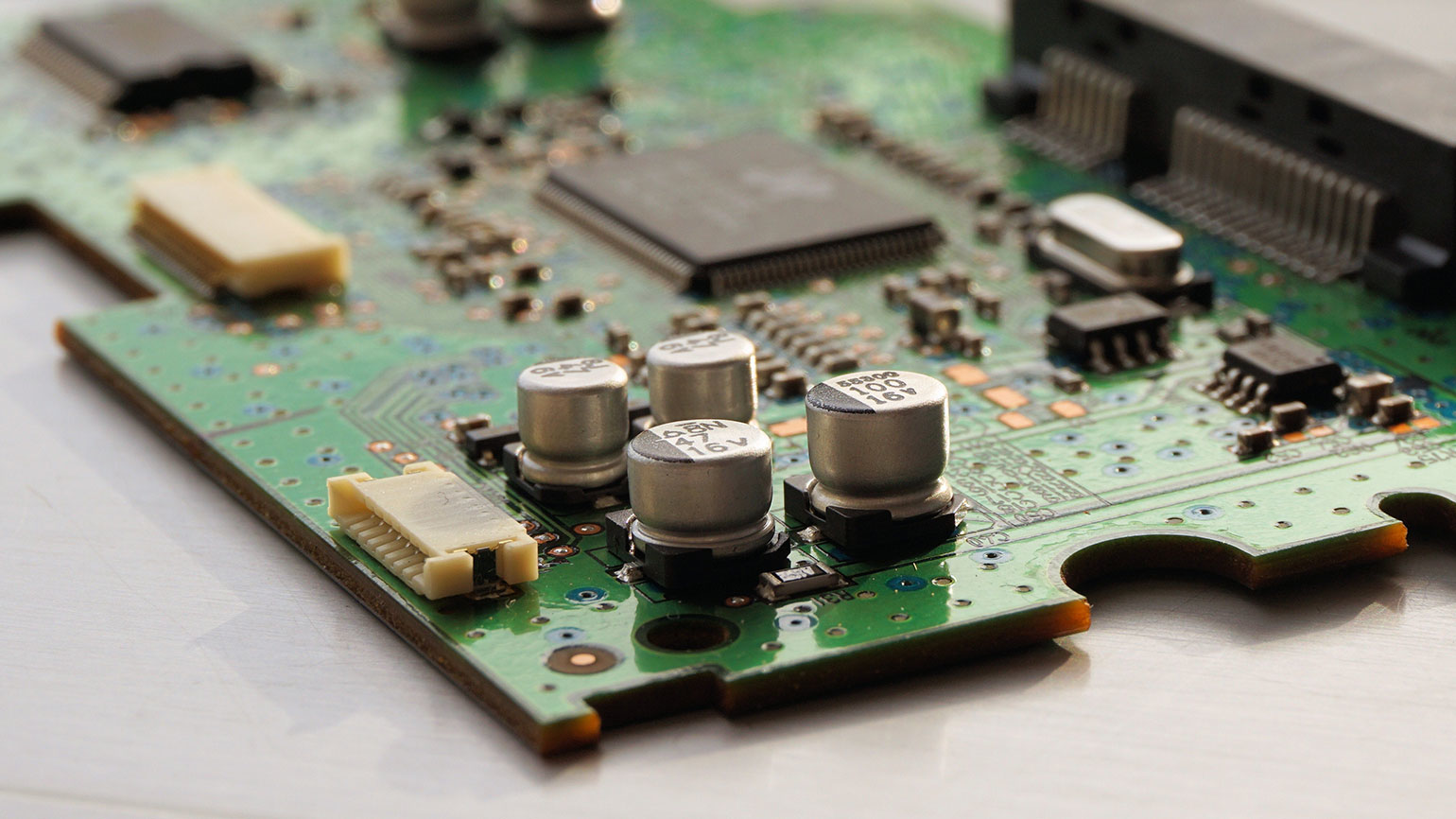

It is vital to note that although used interchangeably, reworking and repairability are in fact two other things. Reworking regularly comes to a component such as a circuit board (PCB), but will also involve complete electronic devices. It regularly refers to the procedure for replacing defective or broken parts on the PCB at the production site, regularly before you leave the production environment.

The term “repairable” means the skill that must be repaired after outdoor sale in the production environment. However, in the context of the production process, it is increasingly vital that each individual product is easy to rework and repair.

Taking on the challenge

It is more vital than ever that brands can rework and weld the factors where disorders arise, than having to discard and dispose of devices every time a component breaks down. With the advent of the new “right of repair” law worldwide, reworking and its role in reducing waste and extending product life will become an even more critical requirement in production in the future.

We have noticed a willingness across teams and Americans to make maintaining customer products less difficult and more cost-effective. The European Commission has recently ratified a new “right of reparation” regulation that will come into force in 2021. Substitution in the law will require brands to make available spare portions, as well as the software or manuals necessary to perform maintenance. Not only will the monopolies that brands have lately on after-sales repair work, but it will also mean that, freed from the risk of cancellation of warranties, more customers will take the issues into their own hands and seek to fix them at home. .

The less difficult it is to disassemble a device without causing damage, the less difficult it will be to repair it. Recent design trends in miniaturization and physical water coverage mean that electronics are unlikely to open without compromising the device’s water resistance or even the structural integrity of the device. This is due to the presence of inflexible joints and joints, as well as thick silencers or glues, which physically impede water penetration but are vulnerable to mechanical damage. As repairability becomes more important, those mechanical responses become increasingly incorrect for use.

Although a device can be safely disassembled for repairs, applying thick, compatible coatings to parts and circuit forums can make it highly unlikely to be fixed by covering the connectors and avoiding parts refueling. And if a tweak is technically possible, in those cases it is unlikely to be effective in loading and, in practical terms, the defective product will likely end up as an electronic waste.

By differentiating customers’ personal tastes and an increasingly difficult legislative landscape, brands are also making a greater emphasis on rework, as it helps reduce waste in the production process and makes the product more sustainable. This is helping brands save cash on fabrics and disposal prices and, in the end, on the profitability of their product lines.

Get rewards

Faced with these challenges, how can brands continue to deliver products with the best degrees of water resistance while benefiting from the customer’s smart will and cost-effective production practices? Using fashionable nano-coating generation brands to produce devices with water resistance grades as smart or better than classic solutions, while maintaining overall retouching capacity.

Nanoco coatings protect PCBs and even entire devices from the inside and eliminate the need for giant mechanical seals that can make a device difficult or harmful to open. Unlike obsolete coatings, nano-coatings are so thin that circuit forums remain available and completely reworked. The increasing use of nano-coating generation in the electronics industry is just one example of how high-tech responses can help manufacturers’ competitiveness in a market where sustainability is a priority for businesses and where consumers and legislators are beginning to prioritize environmental concerns.

Simon Vogt is director of P2i.

By submitting this form and its non-public form, you perceive and agree that the form provided herein will be processed, stored and used to provide you with the requested in accordance with Endeavor Business Media’s terms of use and privacy policy.

As of our services, you agree to obtain magazines, electronic newsletters and other communications about Endeavour Business Media’s related offers, its brands, affiliates and/or third parties in accordance with Endeavour’s privacy policy. Contact us by [email protected] or by mail to Endeavor Business Media, LLC, 331 54th Avenue N., Nashville, TN 37209.

You may opt out of receiving our communications at any time by sending an email to [email protected].

Could FPGAs be the answer to the demise of Moore’s Law? The first component of this two-component series provides a review of the other approaches used to respond to today’s and tomorrow’s repair requests.

What you learn

Moore’s law provided that the processing force of the server processor would double every 18 months. Since the 1980s, this law has been the guiding precept to the creation of fashion network technologies. It’s a no-brainer, until recently. But the expansion of the server processor force is not infinite; is transparent now that this expansion cannot continue. What happens now that Moore’s law is outdated?

The end of an era

In fact, Moore’s Law has been in decline for some time, with activities extending the curve of functionality. It is not only Moore’s Law that is coming to an end in terms of processor functionality, but also the law of Dennard Scaling and Amdahl. The functionality of the processors for more than 40 years and the decline of that legislation are illustrated in the figure.

The graph of how Moore’s Law has evolved over the years. (Source: John Hennessy and David Patterson, Computer Architecture: A Approach Quantitative, 6/ e. 2018)

Gordon Moore made his outstanding initial prediction based on the advent of RISC computing in the 1980s. It faithfully shows a duplication of processor functionality every 18 months. But as clock-by-chip frequency limits began to appear, the use of Dennard scaling and multi-core processors helped make the functionality curve larger. It is vital to note, however, that even at the beginning of the century, we were no longer on the curve of Moore’s Law and that duplication of functionality took 3.5 years in that period.

Another prediction considers the limits of improved functionality that can be achieved with parallel treatment: Amdahl’s law. While parallel execution of a procedure can provide an initial improvement in functionality, there will be an herbal limit, as some execution responsibilities cannot be parallelized. We have recently discovered that these limits take effect when the benefits of using multiple procedures or cores decrease, resulting in an even longer time between functionality enhancements.

The figure above indicates that the processor’s processing force would now take 20 years to double its performance. Therefore, Moore’s law is dead.

Make assumptions about the tilt

True since the 1980s, spanning the entire professional life of many computer engineers, Moore’s Law has been such a reliable and trustworthy phenomenon for so long that many of us take it for granted. Most of us cannot believe in a world where this law is not true.

Aside from a sense of nostalgia, there remains a genuine fear that Moore’s premise of law has led to the creation of entire industries that now have the expectation of a stable improvement in processing performance.

This includes the software industry, which operates in the hope that the processing force will accumulate with knowledge expansion and satisfy the long-term software processing desires. As a result, the effectiveness of software architecture and design is less comprehensive. In fact, layers of software abstraction are being used to make programming and scripts easier to use, but in charge of the processing force.

Take, for example, virtualization. It is a widely used software abstraction of underlying physical resources that creates an additional processing cost. On the one hand, virtualization enables more efficient use of resources. On the other hand, the use of server processors as generic processors for virtualized software execution and input/output knowledge processing imposes a heavy load on processors.

To fully realize the benefits of this dependency, consider the cloud industry and, more recently, the telecommunications industry. The cloud industry was founded on the precept that popular commercial servers (COTS) are resilient enough to take over any type of IT workload. Using virtualization, containerization, and other abstractions, it is imaginable percentages of server resources among multiple tenant clients with “as a service” models.

Telecom companies have noticed these paintings framed with admiration, as well as the good luck of cloud corporations in replicating this technique for their networked paintings with projects such as software-defined network paintings (SDNs), netpainting virtualization for purposes (NFV), and on-premises cloud computing. However, the underlying assumption of the business style here is that as the number of consumers and the volume of paints increases, more servers are simply loaded. But, as the figure obviously shows, the server processing functionality will increase by 3% consistent with the year over the next 20 years. This is well below expectations that the amount of knowledge to be processed will triple over the next five years.

Modern acceleration

At this point, it makes sense to wonder why these slowdown disorders have been more obvious. Cloud corporations seem to succeed without symptoms of functional disorders. The answer is hardware acceleration.

Perhaps the explanation for why cloud corporations adhere so effectively is that they were the first to recognize the death of Moore’s Law and address the functionality issues associated with it. But the pragmatism that has led to success for cloud corporations has also influenced their reaction to this situation. If the strength of the server processor functionality does not increase as expected, they will want to load the processing force. In other words, it’s about speeding up the server hardware.

Turing Award winners John Hennessey and David Patterson discuss the end of Moore’s Law. They cite the example of domain-specific architectures (DSAs), which are particular processors designed to accelerate some application-specific tasks.

In this model, other types of processors adapt to the wishes of express responsibilities that the use of general purpose processors, such as processors, to take over a multitude of responsibilities. An example they use is the TPU (Tensor Processing Unit) chip created through Google for deep neural network inference responsibilities. The TPU chip is specially designed for this task and, as it is at the heart of Google’s business, it makes a lot of sense to download it on a fast processing chip.

Acceleration technologies have become the norm among cloud corporations to increase their workloads. They have graphics processing sets (GPUs) adapted to help a wide variety of programs and are used for hardware acceleration. Network processing sets (UGUs) have been widely used for networks. Both features offer a large number of smaller processors that then break down workloads and parallel them to run on a number of those smaller processors.

In the moment component of this series, we’ll explore a new option to increase workloads in a generation that has been around for some time, namely FPGA. Could be the answer to the disappearance of Moore’s law?

Daniel Proch is Vice President of Product Control at Napatech.

By submitting this form and its non-public form, you perceive and agree that the form provided herein is processed, stored and used to provide you with the order in accordance with Endeavor Business Media’s terms of use and privacy policy.

As of our services, you agree to obtain magazines, electronic newsletters and other communications about Endeavour Business Media’s related offers, its brands, affiliates and/or third parties in accordance with Endeavour’s privacy policy. Contact us by [email protected] or by mail to Endeavor Business Media, LLC, 331 54th Avenue N., Nashville, TN 37209.

You may opt out of receiving our communications at any time by sending an email to [email protected].